GENERAL DETAILS OF PLANT

ABRASIVE BLAST CLEANING

MEGs abrasive shot blast unit is supplied by Euroblast – Pangborn, UK, which is best in the class. Abrasive Automatic steel shot blasting unit has a passage opening of width 2.7 meter and height 1.6 meter. The nominal production capacity is 2 tons/meter at a feed rate of 1.5 meter per minute.

CHEMICAL PRETREATMENT

MEG houses the most technically advanced pretreatment facility in Qatar. Dimension of our PT tanks are 15.5 m (L) x 1.8 m (B) x 3.0 m (D) which allows us to pre-treat a material size of 15 m x 1.7 m x 2.9 m.

KOERNER KVK from Austria supplied MEG’s Pretreatment Tanks. KVK’s manufactures the toughest tanks in the world.

ENCAPSULATED PRETREATMENT

Pretreatment is done in a completely enclosed set up to prevent the chemical fumes spreading in the plant. This makes MEG a pleasant and environment-friendly galvanizing plant.

HCI NEUTRALISATION AND FLUX TREATMENT

MEG has also installed an HCI Neutralization and Flux Regeneration Plant. These units are capable of regenerating more 90% of spent chemicals, which reduces the wastage and increases the economic value alongside reducing the environmental damage.

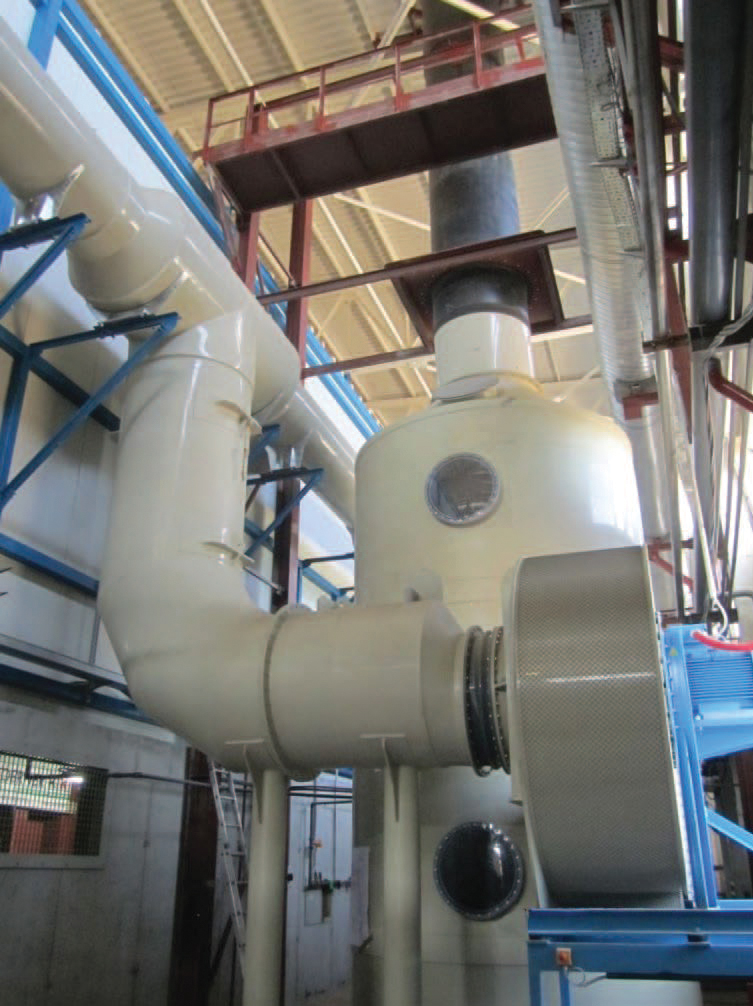

FUME EXTRACTOR AND SCRUBBER

Scrubbing the exhaust air prevents the release of aggressive and harmful vapors into the environment. Vapors and gases are absorbed in the scrubbing liquid and returned to the substance circuit.

Benefits:

– Operation without wastewater

– Savings on fresh acid through return of scrubbed out acid into the process

– No additional chemicals

DRYER OVEN

After chemical pretreatment, all the material jigs are heated to a temperature of 100 to 120 degree Celsius to remove the moisture content. MEG’s dryer oven comes with an automatic temperature stabilizing system which maintain the temperature inside the oven almost constant.

GALVANIZING

Once the steel has been completely cleaned and fluxed, it is ready for immersion in the zinc bath. The galvanizing kettle contains zinc specified to ASTM B6. The galvanizing kettle is heated to a temperature ranging from 445-455ºC, at which point the zinc is in a liquid state. The steel products are lowered into the galvanizing kettle at an angle, and stay in the bath until the steel heats to the bath temperature. Once the diffusion reaction of iron and zinc is complete, the steel product is withdrawn from the zinc kettle. The entire dip usually lasts less than ten minutes, depending upon the thickness of the steel. For first time in Qatar, LEAD FREE Galvanizing is being introduced in Middle East Galvanizing. NO LEAD shall be added to the Zinc bath.

ZINC DUST FILTER

It is intended for removing of white fumes containing zinc dust particles from area above zinc melt and it consists of exhausting pipes, filter with air pressure regeneration and fan.

POST TREATMENT

MEG includes two post treatment process namely quenching and passivation.

MATERIAL HANDLING

MEG uses movable loading and unloading stations. So that we can always optimize the floor space as per material sizes and quantity by adjusting the loading stations.